Tension Leveler Line

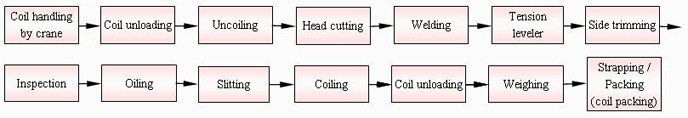

It is part of finishing line of cold rolled strip production, used for leveling, finishing and improving strip flatness, cutting off the off-gauge strip head and tail, trimming the strip edge and dividing the coil according to the coil weight required by the users.

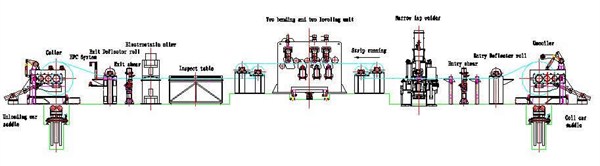

When the coil is uncoiled, the strip runs to the crop shear to cut off the off-gauge portion of strip head and tail and goes to the welder to let the tail of previous coil be welded with the head of next coil; after passing through the tension leveler to undergo two bending and two leveling sequences, the leveled coil enters the rotary side trimmer where the edge is cut, and then runs to inspection table before entering the electrostatic oiler. The oiled coil is coiled by the coiler; as the required coil weight is reached, the strip is cut by the dividing shear. The speed of the unit can come up to 200m/min and the strip to be processed can be 1250mmm wide and 0.18~0.8 mm thick.

Main characteristics

- The unit has complete equipment configuration, which can execute stretching, leveling, side trimming and oiling, etc.

- CPC installed aligns strip running and EPC ensures the product coiling quality at the line exit.

- VVVF speed control system for drive and friendly HMI are selected for the line.

Technical data

Strip thickness: 0.18~0.8mm

Strip width: Entry: 700~1250mm Exit: 700~1250mm

Coil inside diameter: Entry: ф610/ф508mm Exit: ф508mm

Coil external diameter: Entry: max.ф1900mm Exit: max.ф1500mm

Coil weight: Entry: max.22t Exit: 6~10t

Process speed: 150~200m/min